LED UV products have achieved surpasses in many aspects

1 more environmentally friendly

Basically no volatile solvents, zero VOC emissions. In addition, LED curing uses semiconductors to emit light, does not contain mercury, and uses longer ultraviolet light. During the period, ozone is not generated, and there is no environmental pollution factor, and the environmental performance is excellent.

2 more energy efficient

LED light curing directly converts electric energy into UV light. The light energy is highly concentrated in a specific ultraviolet light band, and the effective luminous rate is high. LED light curing consumes power only when irradiated, and the standby consumption is nearly zero. The overall energy consumption is more than traditional mercury. Lamps and gallium lamps are reduced by more than 70%.

3 Good polishing

The curing method of LED light-cured wood lacquer is essentially a photo-accelerated polymerization curing technology, with high light crosslinking density and excellent sandability, especially suitable for special-shaped sanding machines.

4 Comprehensive cost reduction

The LED light-curing paint film can be cured quickly, saving time and energy, and the lamp tube will only light up when ultraviolet light is needed, which saves power consumption and prolongs the life of the lamp tube, reducing enterprise labor and operating costs. In addition, the LED light source has no mercury or accessories such as lampshades, which effectively reduces equipment maintenance costs.

5 Wide application range

LED is a cold light source, which can effectively prevent the substrate from shrinking and deforming due to overheating, and has a wide adaptability to materials. Products such as logs, laminates, and stickers can be coated.

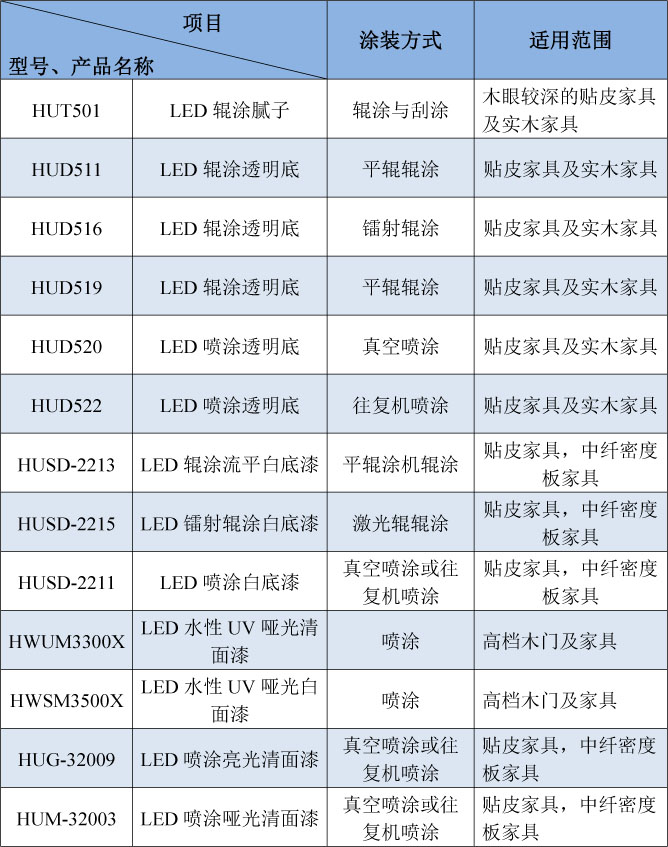

"Shuangxiong" water-based matte varnish

Product Numbers: HWUM3300X Construction method: spraying LED light curing light intensity: 4000-4500mw/cm2

"Two Heroes" Transparent Primer

Product Numbers: HUD522 Construction method: reciprocating spraying LED curing light intensity: 4000-4500mw/cm2